Created as a result of the merger between Doosan Machine Tools and DN Automotive, the new entity will build on the impressive strengths and legacies of its two predecessor companies. DN Solutions continues to make efforts to secure competitiveness, the growth engine for attracting new customers, based on technology recognized by customers.

Applications

Discover the applications for our AVATEC machines

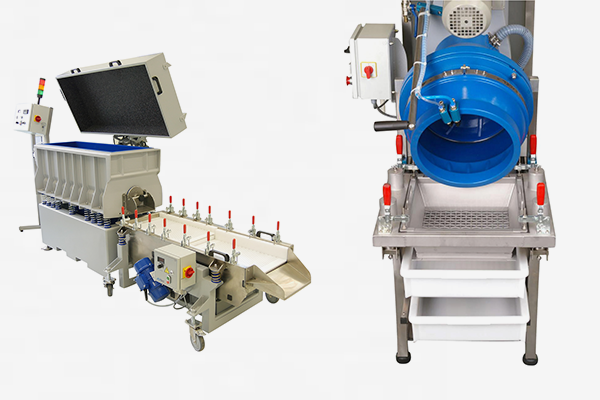

Disc Finishing Machines

Workpieces and abrasives are loosely placed in an open-topped working container and placed in a toroidal flow through the tray formed as a disc. The centrifugal force accelerates the workpieces together with the grinding wheels to the standing streamlined inner wall of the working container.

Due to their different density, the workpiece and the abrasive body perform a relative movement. This dynamic flow allows high, targeted material removal with very short processing times compared to vibrators or drums.

Trough Vibrators

In the vibratory process, the workpieces and the abrasive are loosely placed in an open-topped working container (trough) and offset by imbalances in short oscillations, which forces the mixture in a screw or ringing toroidal (long or round trough).

Due to their different densities workpieces and grinding bodies perform a relative movement, which allows material removal. Vibrators are universal vibratory finishing machines and can be used for a variety of workpieces and machining targets that cause problems in drum and centrifugal grinding. They are particularly suitable for low-cost high-gloss polishing of highly sensitive workpieces, thi smeans from rough pre-sanding to the production of electroplated surfaces.

Round Trough Vibrators

Workpieces and grinding media are put into motion in an open-topped trough. Due to imbalances the trough is set into short vibrations which forces the mixture into spiral- and toroid-shaped motion. Finishing is achieved by a relative movement of workpieces and grinding media caused by different specific gravity.

Vibratory finishing systems are universal and can be used for a variety of workpieces and processing objectives that would cause problems for drum and centrifugal disc systems. Vibratory finishing systems are particularly suitable for low-cost high-gloss polishing of sensitive workpieces. The applicability of this technology ranges from rough pre-grinding to electroplate finishes.

Separation

A good separation of workpieces and grinding wheels after machining is crucial for workpiece quality and system capacity.

We offer a variety of manual and automated separation options and are happy to assist you in choosing the optimal solution for your process.

Consumables

The choice of process medium in quality and form is the key to the optimum finish achieved by the interaction of workpiece and machine. A large number of grinding and polishing media as well as granulates, compounds and additives are available to meet the requirements of your process.

The following media are a selection of the wide assortment we offer. Other sizes and shapes are available on request.